Understanding the Foundation: Basic Gasket Types and Their Applications

At Striv Solutions, we believe that understanding the fundamentals is key to achieving optimal performance and preventing costly failures in any industrial system. When it comes to sealing, gaskets are the unsung heroes, silently working to maintain integrity, prevent leaks, and ensure efficiency. But with a seemingly endless array of materials and designs, how do you choose the right one?

This guide will demystify the world of gaskets by focusing on the most basic and commonly encountered types, explaining their characteristics, and highlighting their typical applications. By the end, you’ll have a clearer picture of how these essential components contribute to reliable operations across various industries.

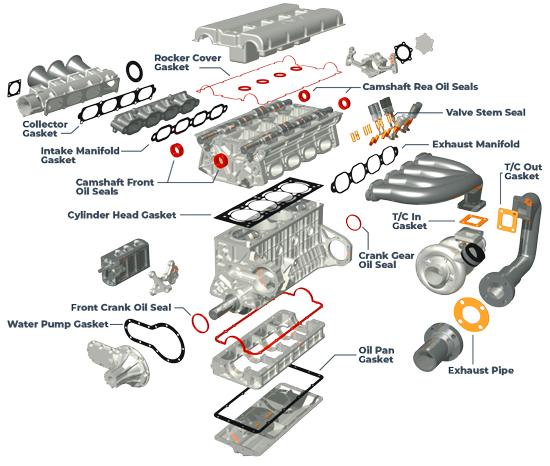

What Exactly is a Gasket?

Before diving into types, let’s define our subject. A gasket is a mechanical seal that fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. They are designed to conform to imperfections on the mating surfaces, creating a tight seal that withstands pressure, temperature, and chemical exposure.

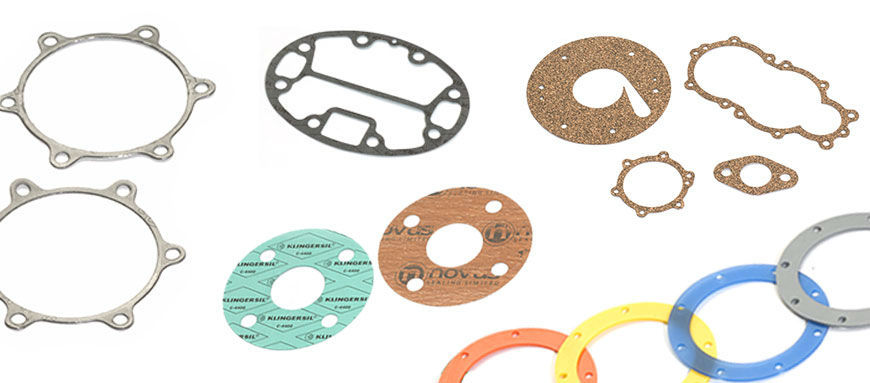

1. Non-Metallic Gaskets (Soft Gaskets)

These are arguably the most common and versatile type, ideal for applications that don’t involve extreme temperatures or pressures. They are typically cut from sheets of flexible material and are known for their excellent conformability.

Common Materials & Applications:

Rubber (Neoprene, EPDM, Nitrile, Silicone, Viton®):

Characteristics: Highly flexible, good compression set, excellent sealing properties. Different rubber types offer varying resistance to oil, chemicals, ozone, and temperature.

Applications:

Neoprene: General-purpose sealing, weatherstripping, good resistance to oils and sunlight.

EPDM: Excellent for outdoor use, water, steam, and mild chemicals; common in HVAC and automotive cooling systems.

Nitrile (Buna-N): Superior oil and fuel resistance; widely used in hydraulics, fuel systems, and general industrial applications involving petroleum products.

Silicone: Outstanding high and low-temperature resistance, good for food-grade applications and medical devices due to its inertness.

Viton® (Fluoroelastomer): Exceptional resistance to aggressive chemicals, high temperatures, and fuels; often found in chemical processing and aerospace.

Compressed Non-Asbestos Fiber (CNAF):

Characteristics: Made from synthetic fibers (like aramid) bonded with rubber. Replaced asbestos gaskets due to health concerns. Offers good compressibility and chemical resistance, suitable for medium pressure and temperature applications.

Applications: Pipe flanges, pumps, valves in water, steam, oil, and gas systems. A versatile choice for many industrial sealing needs.

Graphite (Flexible Graphite):

Characteristics: Excellent high-temperature resistance, chemical inertness (except strong oxidizers), good compressibility, and thermal conductivity. Often comes as a sheet or reinforced with a metal core.

Applications: High-temperature steam, chemical processing, exhaust systems, and general industrial sealing where heat is a major factor.

PTFE (Polytetrafluoroethylene – e.g., Teflon™):

Characteristics: Extremely chemical resistant, non-stick, wide temperature range, low friction. Can be rigid, but variants like expanded PTFE (ePTFE) offer better compressibility.

Applications: Highly corrosive chemical services, pharmaceutical, food and beverage industries where cleanliness and chemical purity are paramount.

Cork:

Characteristics: Excellent compressibility, good oil and fuel resistance, low cost. Often blended with rubber for enhanced properties.

Applications: Automotive oil pans, valve covers, electrical transformers, and low-pressure sealing where flexibility and resistance to hydrocarbons are needed.

2. Semi - Metallic Gaskets

These gaskets combine metallic and non-metallic materials, offering a balance of strength, resilience, and sealing capability for more demanding applications.

Spiral Wound Gaskets:

Characteristics: Constructed by spirally winding a V-shaped metallic strip (usually stainless steel) with a non-metallic filler material (like graphite or PTFE). Highly resilient, excellent for thermal cycling, and high-pressure applications.

Applications: High-pressure and high-temperature pipe flanges, heat exchangers, valves in power generation, oil & gas, and chemical plants.

Camprofile Gaskets (Grooved Gaskets):

Characteristics: Feature a solid metal core with concentric grooves, faced with a softer non-metallic layer (graphite, PTFE). Provides excellent sealing even with low seating stresses, resilient, and reusable (by replacing the soft layers).

Applications: High-pressure and temperature applications, particularly where lower bolt loads are preferred, such as heat exchangers, pressure vessels, and large diameter flanges.

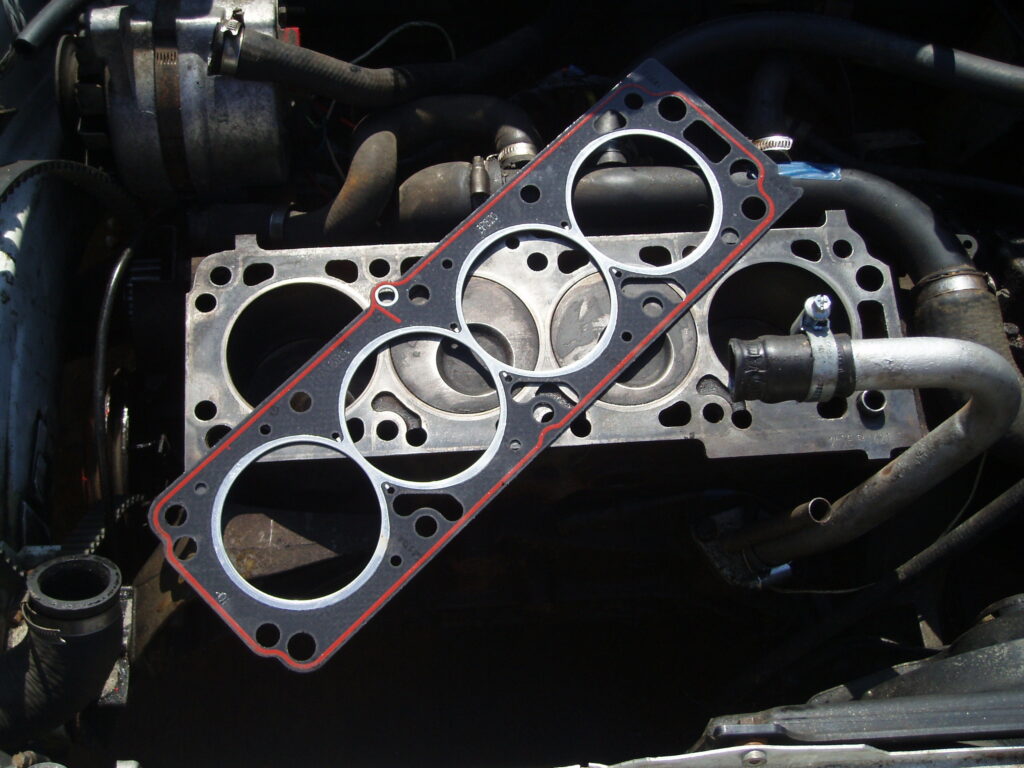

3. Metallic Gaskets (Hard Gaskets)

Made entirely of metal, these gaskets are designed for extreme pressures and temperatures where other gasket types would fail. They rely on deformation of the metal to create a seal, often requiring very high bolt loads.

Common Types & Applications:

- Ring Joint Gaskets (RTJ):

- Characteristics: Solid metal rings (oval or octagonal cross-section) designed to fit into machined grooves on flanges. They create a metal-to-metal seal by plastic deformation when compressed. Extremely robust.

- Applications: High-pressure and high-temperature oil and gas pipelines, refineries, chemical plants, and steam services.

- Corrugated Metal Gaskets:

- Characteristics: Made from thin metal sheets pressed into a corrugated profile. Can be supplied bare or with a soft coating. Offer some resilience and can compensate for minor flange irregularities.

- Applications: Exhaust systems, heat exchangers, and applications requiring robust sealing with some degree of flexibility.

Choosing the Right Gasket: Key Considerations

Selecting the correct gasket for your application involves more than just identifying the type. You must also consider:

- Temperature: Minimum and maximum operating temperatures.

- Pressure: Maximum operating pressure.

- Media: The type of fluid or gas being sealed (chemical compatibility is crucial).

- Flange Type: The design and condition of the mating surfaces.

- Bolt Load: The available compression force.

- Service Life: Expected duration of operation.

- Cost: Balancing performance with budget.

At Striv Solutions, we leverage our expertise in gasket manufacturing to guide you through these choices, ensuring you get a sealing solution that is not just effective but also durable and cost-efficient for your specific needs.

How do I know if my gasket needs to be replaced?

Common signs include visible leaks, loss of system pressure, reduced efficiency, or physical damage to the gasket itself (cracking, hardening, swelling, or extrusion). If you’re disassembling a joint, it’s generally good practice to replace the gasket, especially if it’s a non-metallic type.

Can I reuse an old gasket?

It is generally not recommended to reuse gaskets, particularly non-metallic and semi-metallic types. Gaskets are designed to deform and conform to irregularities under initial compression, and once that set is taken, they lose their ability to reseal effectively. Metallic gaskets (like RTJs) might sometimes be reused if they show no signs of deformation or damage, but it’s risky for critical applications.

Why is chemical compatibility important for gaskets?

Chemical compatibility is critical because if the gasket material reacts with the fluid or gas it’s sealing, it can degrade, swell, shrink, or dissolve. This leads to seal failure, leaks, system contamination, and potentially dangerous situations. Always match the gasket material’s resistance to the media it will encounter.