Gasket Material: The Foundation of Reliable Sealing Solutions

In every industry where fluids, gases, and chemicals need to be contained, the choice of gasket material can make the difference between smooth operations and costly downtime. We understand that a high-quality gasket material is not just a product—it’s a safeguard for efficiency, safety, and performance. With decades of expertise, we supply premium to industries worldwide, ensuring each application gets the most suitable solution.

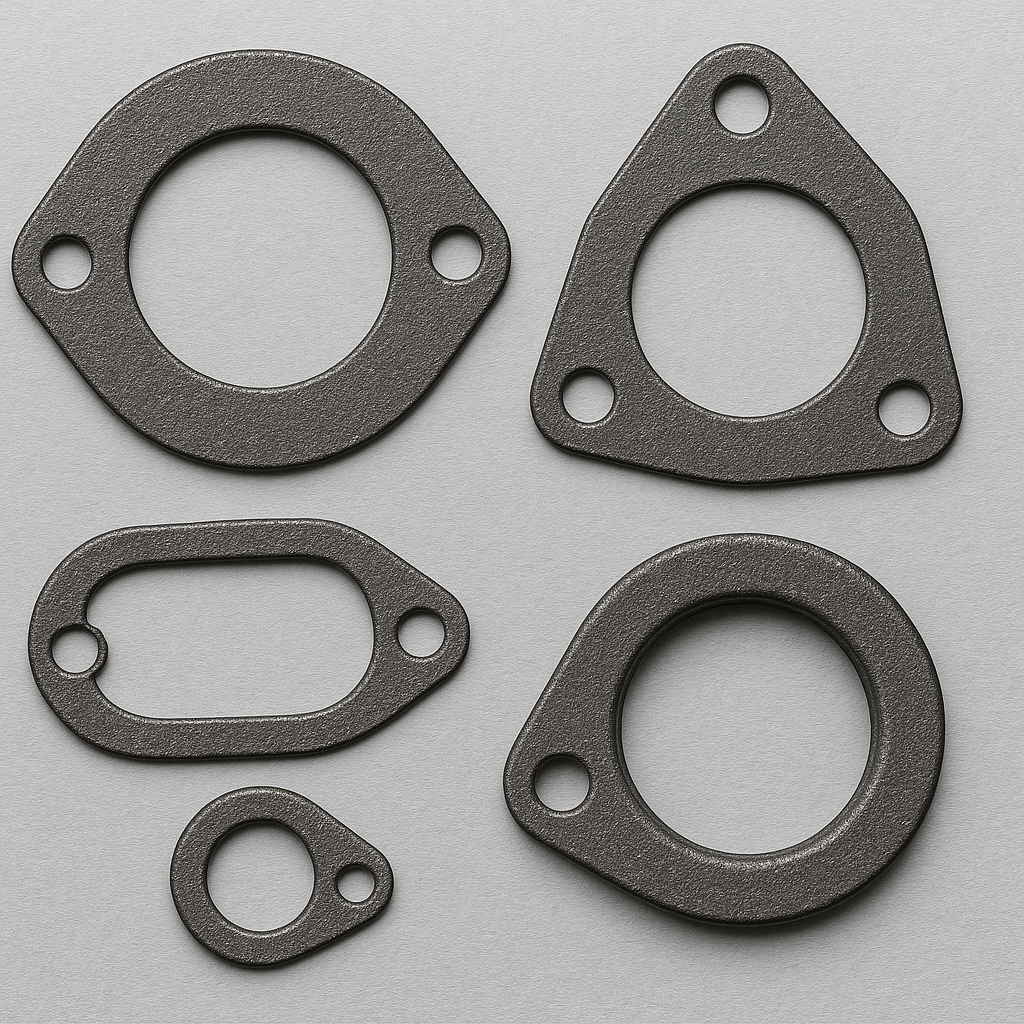

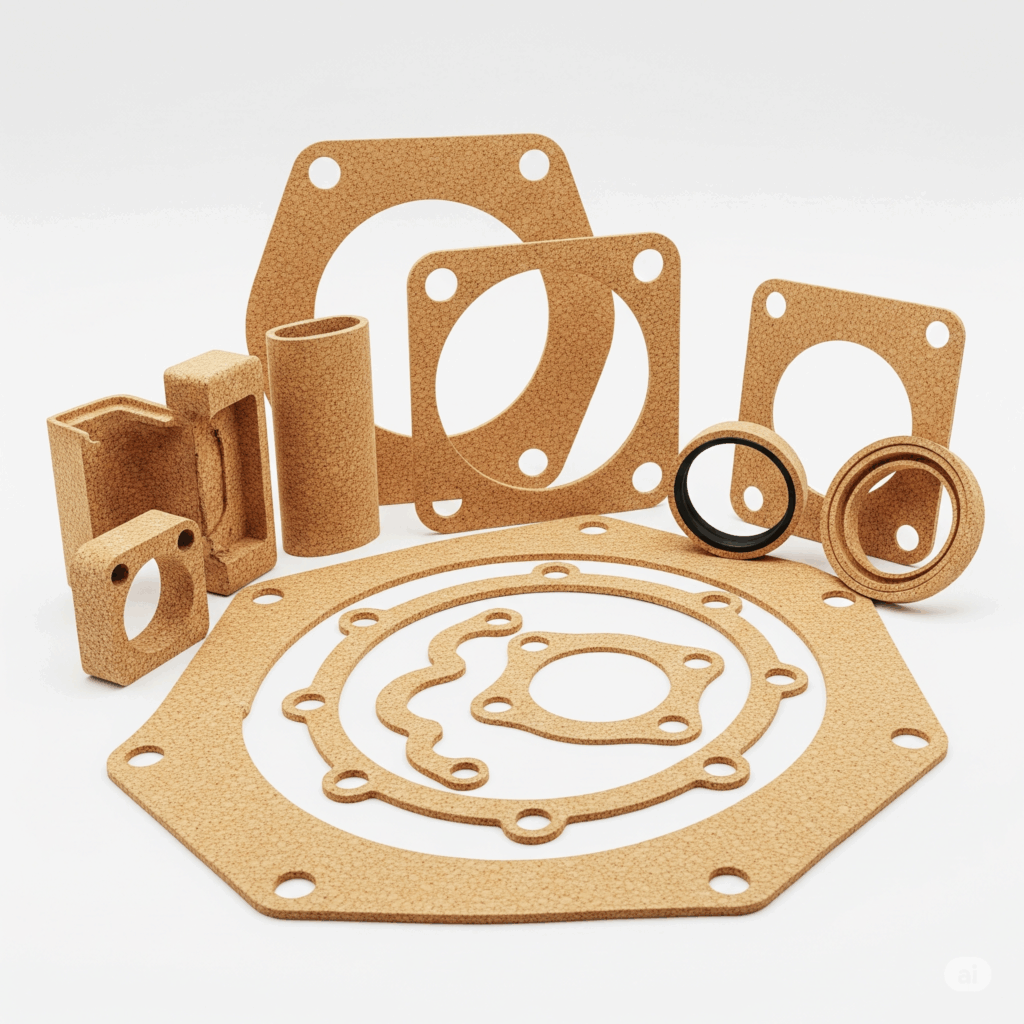

What is Gasket Material?

A gasket material is the base substance from which a gasket is manufactured. It acts as the sealing medium between two surfaces, preventing leakage under varying temperatures, pressures, and environmental conditions. The right gasket material ensures long-term performance, and resistance to operational stresses.

- Rubber Gasket Material

Flexible and versatile, rubber is widely used in water, oil, and gas applications. Variants like EPDM, Nitrile, and Silicone offer specific resistances to chemicals, weather, and temperature.

2. Graphite Gasket Material

Known for its exceptional heat tolerance, graphite is ideal for high-temperature, high-pressure environments like power plants and refineries. It resists chemical attack while maintaining sealing integrity.3. Cork Gasket Material

Lightweight and compressible, cork works well in automotive, pump, and compressor applications. It offers excellent oil resistance and adaptability to irregular surfaces.4. Metallic Gasket Material

Stainless steel, copper, and other metals form metallic designed for extreme conditions. They are common in turbines, heat exchangers, and heavy machinery.5. PTFE (Teflon) Gasket Material

Resistant to almost all chemicals, PTFE is the go-to choice for food processing, pharmaceuticals, and aggressive chemical applications.

Factors to Consider When Choosing the Right Gasket Material

Selecting the best gasket material requires evaluating the application’s operating environment:

Temperature Range: The material must withstand operational heat without deforming.

Pressure Tolerance: High-pressure environments demand durable materials that won’t fail under stress.

Chemical Resistance: The material should remain stable when in contact with specific fluids or gases.

Environmental Exposure: UV light, ozone, and weather conditions can degrade certain materials.

Compliance Standards: ISO and ASTM-certified materials ensure safety and performance reliability.

Why Striv Solutions Leads in Gasket Material Supply

Since 1995, Striv Solutions has been a trusted supplier of gasket material for diverse industries, from automotive and petrochemical to food processing and marine engineering. Our commitment to quality, backed by our ISO 9001:2015 certification, ensures every gasket material we deliver meets strict international standards.

Our Strengths in Gasket Material Supply

Extensive Expertise: With over 25 years in the sealing industry, we understand the science behind materials and their applications.

Custom Solutions: We supply tailor-made gaskets for unique engineering challenges.

Quality Control: Every gasket undergoes rigorous inspection before delivery.

Global Reach: Our supply network serves clients across multiple continents.

Industries That Rely on Our Gasket Material

Our gasket materials are trusted in industries such as:

Automotive: For engine sealing, exhaust systems, and transmission components.

Oil & Gas: For high-pressure, high-temperature sealing in pipelines and refineries.

Power Generation: For steam systems, turbines, and heat exchangers.

Food & Pharmaceutical: For hygienic, non-contaminating sealing solutions.

Marine: For corrosion-resistant sealing in harsh saltwater environments.

The choice of material is critical to ensuring long-lasting, safe, and efficient sealing. Whether your priority is heat resistance, chemical stability, or mechanical strength, Striv Solutions can provide the perfect material for your application. By combining technical expertise, rigorous quality standards, and customer-focused service, we make sure that every material we deliver meets or exceeds expectations.

Contact us today to explore our complete range of high-performance gasket materials designed to keep your operations running smoothly.